High Quality for China Third Party Inspection Company/Production Inspection

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for High Quality for China Third Party Inspection Company/Production Inspection, Honest cooperation along with you, altogether will produce happy tomorrow!

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for China Quality Control, Inspection Service, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We've been able to develop new items continuously to a higher level to satisfy different needs of customers.

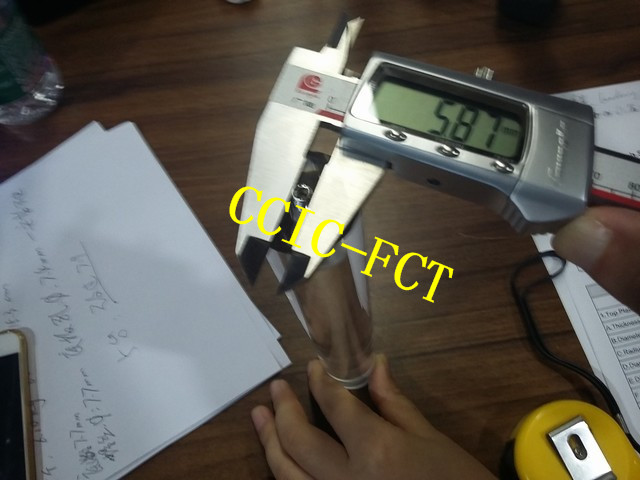

PRE PRODUCTION INSPECTION

INITIAL PRODUCTION INSPECTION

The Pre-Production Inspection (PPI) also called initial production, is the inspection process starting with a through detailed assessment and inspection of raw materials and components.It happens when the the identification and the evaluation of your new vendor/factory is completed and right before the beginning of mass production. A Pre Production Inspection ensure that your supplier is able to start the production on schedule and your specifications are understood by the factory and to prevent any potential flaws in the production resources, materials, schedules, management and more. We will also check on the quality of components, materials, and accessories at the beginning of the production against clients’ specifications and/or reference samples.

Our main check points are as below:

1.Check quality and quantity of raw material and components;

2.Mainly see factory production capacity and quality control ability;

3.Also check some finished products and Semi-finished products;

4.monitor the production schedule;

5.Recommendation.

Why should I need Pre Production Inspection?

Before production, helping you make sure the raw materials and components will meet your specifications and are available in quantities sufficient to meet the production schedule.

- Avoid misunderstanding.

- Make sure your requirements are well understood.

- Avoid usage of wrong material, wrong colors etc., verify that your product specifications are being met early.

- Implement corrective actions as soon as possible.

- Avoid unexpected costs & delays.

More from Our Customer Inpsection Cases

Ready to find out more? Contact us for a quote!

CCIC-FCT thirty party inspection company,provide inspection service to global buyers.