Factory source Professional Pre-Shipment Inspection -Garbage Bin

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for Factory source Professional Pre-Shipment Inspection -Garbage Bin, We welcome customers all around the word to speak to us for long run company interactions. Our items are the best. Once Selected, Perfect Forever!

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for China Quality Control Inspection and Inspection, We insist on "Quality First, Reputation First and Customer First". We're committed to providing high-quality products and solutions and good after-sales services. Up to now, our merchandise have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

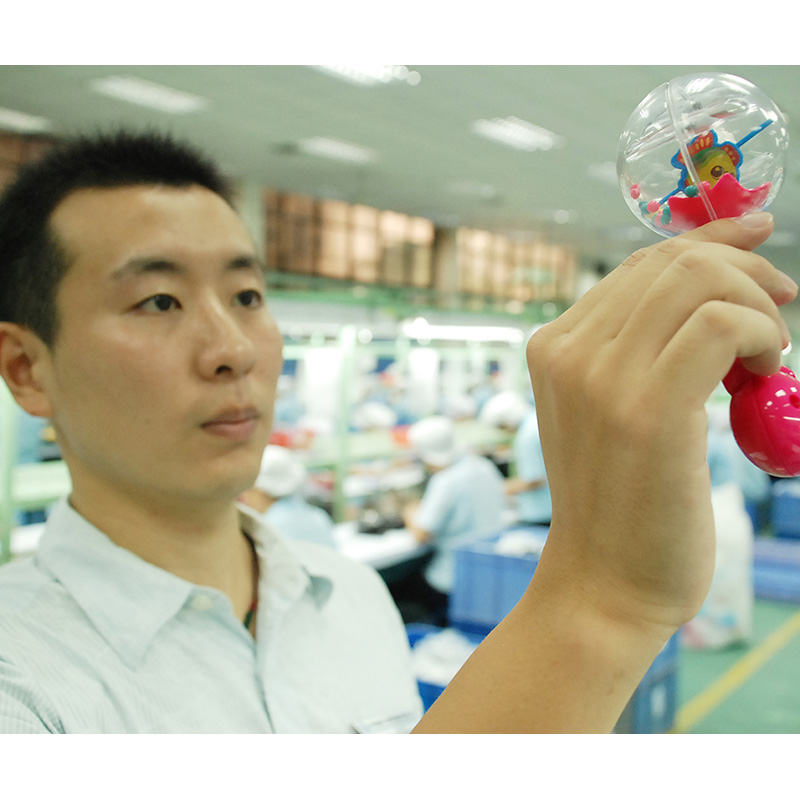

During Production Inspection

Solve the quality problems during manufacturing process to prevent further issues or defects

What is DUPRO?

During production inspection (DUPRO) sometimes referred to as Inline Product Inspection or In Process Inspection (IPI) or During Production Check.A visual check on the quality of components, materials, semi-finished and finished products when at least 10%-20% of the order has been completed. The production batch and those products in the line would be randomly inspected for possible defect. If any problem occurs, identifies the deviation and provides advice on the corrective measures that are necessary to ensure a uniform batch quality and a quality product.

What will we check in DUPRO?

* DUPRO normally done as the product is through the finishing process. That means inspection shall be conducted when 10%-20% of goods are finished checking or packed into the polybag;

* It shall find out defects in the earliest stages;

* Record the size or color, which will not be available for inspection.

* Check semi-finished goods on every production processes. (production status);

* Proportionally and randomly check the goods during the inspection (Level 2 or otherwise specified by applicant);

* Mainly search the cause of defect and suggest corrective action plan.

Why you need a DUPRO?

* Find out defects in the earliest stages;

* Monitor the production speed

* Deliver to customers on-time

* Save time and money by avoiding hard negotiations with your supplier

More Customer inspection case Sharing

Contact us to get a copy of our DUPRO inspection checklists

CCIC-FCT thirty party inspection company,provide inspection service to global buyers.